Our History

Find out more about how our company was established and what led to the development of our innovative hands free lifting products.

What We Do

Hands Free Load Orientation

Custom Applications

If you have a lifting challenge, we will work with your company to design and develop a hands free lifting solution.

Precision Engineering Builds

Whatever solution is required, we have the capability to produce the designed system

Our History

We are a team of engineers based in Scotland with a reputation for lateral thinking solutions for practical engineering problems.

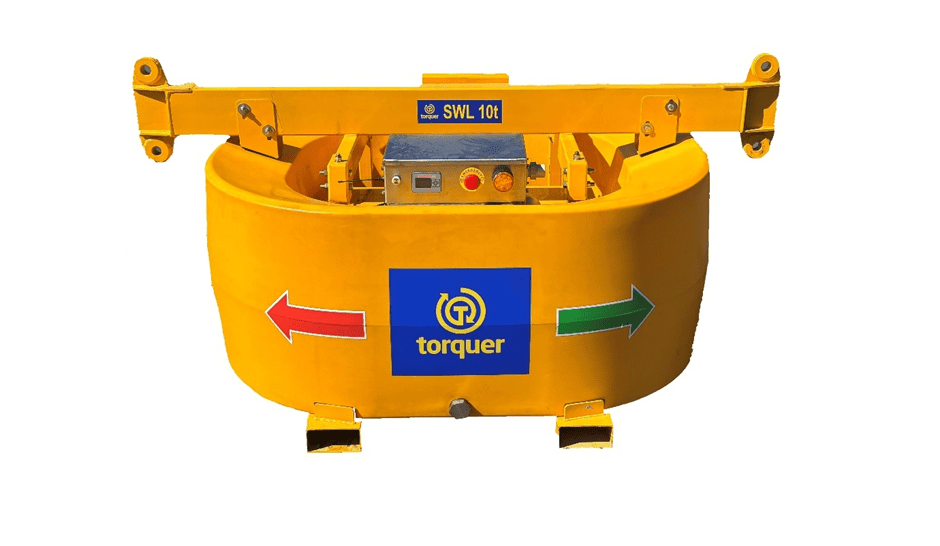

Torquer was originally set up to design, develop, build and launch a specialised product, the HALO, to solve a well-known and longstanding problem facing the Oil & Gas sector, i.e. controlling the orientation of containers as they are loaded to and from offshore installations. This is a major problem for the sector and currently, serious health and safety issues exist and there is a push in the offshore industries towards handsfree lifting operations.

The Construction industry also faces similar health and safety challenges related to controlling load orientation which our product solves. The recent HOSASS (Hands Off, Step Away, Safe Space) initiative launched by ILLAPG (Industry Lifting Lead AP Group) highlights the urgent need to keep personnel away from moving loads to prevent injuries.

Torquer provides a very simple, low tech, low cost solution for which there is strong interest from both the Construction and O&G sectors, as well as from health and safety personnel in major organisations.

buy outFollowing the development of a number of remote controlled working prototypes the company designed and fabricated pre-production HALO units, with which we carried out extensive and successful field trials both in the UK and USA.

Our company was acquired in 2024 by Helmerich & Payne, currently the largest O&G drilling company in the world, who have been supporting the developments for several years, enabling us to bring our products to market. However, Torquer has recently undergone a management buy out, and is now operating independantly from H&P. The latest standard production unit is the HALO 2000SP, which is capable of orienting 99% of loads on a construction site. However, we have recently developed a modular system which can be adapted to handle loads of various weights and sizes. Also, because of our strong engineering R&D and solution based perspective, custom units can be built to suit specific customer applications. Additionally, we are continually working on improving the performance and capability of the system.

With our focus on hands free lifting, we developed another product, the SPEAR & Catcher, which provides a purely mechanical lifting unit for auto connect/disconnect and lifting of a load. This system is completely scalable, and is currently being used by a major construction company for lifting precast concrete blocks up to 100Te at a large construction project in the UK. It was recently voted 3rd best new product at the 2025 UK Concrete Show.

Benefits

Safer Lifting

With remote controlled operation, no-one needs to stand near the load being lifted, reducing the risk of injury to workers.

Easy to Use

Within a few minutes, the simple radio remote handset can be used easily to provide very accurate orientation control.

Efficient Operations

Eliminating the need for tag lines means less time to lift and position loads, especially at height or in hazerdous locations, making lifts more cost effective.